- (651) 429-1100

- [email protected]

- Mon - Fri: 8:00 - 17:00

Ongoing Corrosion? It is Not Too Late!

Our Topical Solutions Are Perfect For Existing Structures

Click HereCorrosion Solutions and Beyond

Be At the Ready With Our Customizable Specialty Corrosion Solutions Designed To Fit Your Specific Job's Needs

Click HereDon't Just Patch... Protect (or Prolong)

Conventual Patch Repairs May Create A Need For More Repairs, But Not With Our HPRS

Click HereCortec®... Not just a Manufacturer

We are Here To Elevate Your Corrosion Mitigation Strategy. Click Here To Know What We Can Offer

Click HereOur Story

Cortec® has been protecting structures for more than 35 years. Whether it is new construction, existing structures, or a unique problem, our tailored and environmentally responsible solutions can help you meet your service-life (or durability) goals.

Our Expertise

Unlike many other concrete corrosion inhibitors on the market, the MCI® lineup includes a selection of admixtures and surface applied corrosion inhibitors (SACIs) that are certified to meet ANSI/SNF Standard 61 for drinking water system components. It also includes the only corrosion inhibiting admixture on the market that is a USDA Certified Biobased Product.

Our dedicated team is ready to serve and support you on specific project issues. Backed by a long track record of innovation and leadership in concrete corrosion control, our global presence has expanded to help contractors meet design life requirements in some of the most aggressive regions of the world.

MCI® Technology & Solutions

Cortec Corporation’s patented MCI® (Migrating Corrosion Inhibitor) Technology protects reinforcing metal in concrete from corrosion. Often, corroding rebar in deteriorating concrete is the cause of costly repairs, financial losses, injuries, and even deaths, but Cortec® has the corrosion solution. MCI® greatly extends the service life of new and existing structures by proactively delaying the onset of corrosion and keeping rates low after initiation. Cortec MCI® products maintain structural integrity, rehabilitate vulnerable structures, and alleviate environmental concerns.

How Does MCI® Technology Work?

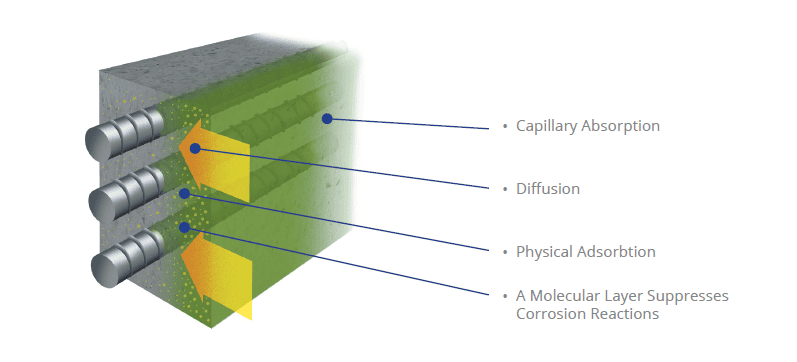

MCIs are based on amine technology (amine alcohols and amine carboxylates). They are classified as mixed inhibitors, meaning they affect both anodic and cathodic portions of a corrosion cell. MCI® is applied in many forms including as a concrete admixture or a topical treatment. It moves as a liquid through the concrete matrix via capillary action and migrates in a vapor phase throughout the concrete pore structure. When MCI® comes in contact with embedded metals, it has an ionic attraction to it and forms a protective molecular layer. This film prevents corrosive elements from further reacting with the reinforcement and also reduces existing corrosion rates, greatly extending concrete service life.

Durability and Sustainable Construction

Cement’s carbon footprint and its impact on the planet are global concerns. Building long-lasting structures that can withstand harsh environments will reduce the need for new cement production to repair and replace these structures. Using MCI® solutions leads to improved corrosion resistance, enhanced durability, and therefore greater sustainability in construction. MCI® is also an excellent addition to building projects around the world seeking to meet green building rating system requirements such as LEED, Estidama Pearl, and BREEAM systems.

Environmentally Responsible Concrete Corrosion Protection Solutions

MCI® admixtures work independently of chlorides, protect even when cracks occur, and can actually delay set time for better workability.

MCI® can be applied to existing structures as a surface treatment that reduces corrosion rates.

MCI® is important for ensuring the longest possible lifespan of concrete restoration projects.

In addition to Migrating Corrosion Inhibitors, Cortec® offers products for concrete cleaning, rebar storage, and rust conversion.