CASE HISTORY SPOTLIGHT: Case History #121: Plankinton Avenue Parking Ramp Preservation

August 10, 2022

In 1999, the Plankinton Avenue parking ramp in downtown Milwaukee was deteriorating and rebar had rusted in the concrete due to deicing salt. The city wanted an economical way to renovate and protect the ramp with minimal downtime while using the best products and procedures on this valuable source of revenue. The renovation contractor applied MCI®-2020 to the concrete decks as an important part of the concrete repair system to extend structural service life and reduce maintenance by forming a corrosion inhibitor barrier on steel reinforcement.

Read the full case history here.

For a PDF version please click here.

Keywords: rusted rebar in concrete, parking ramp preservation, deicing salt rust, concrete renovation, Cortec MCI, From Grey to Green, MCI-2020, concrete repair, corrosion inhibitor

Inaugurated the Peljesac Bridge in Croatia, Protected with Cortec’s MCI® Technology Featured in IPCM Magazine

PRESS RELEASE: Value Engineering with MCI®-2020: Counteracting Shortages, Cutting Costs

August 9, 2022

With rising inflation, material shortages, and the ever present demand of staying within budget, engineers and construction companies today are increasingly turning to the concept of value engineering. One important facet of this effort is safely finding ways to extend the useful service life of existing structures. When it comes to maintenance and repair, silane shortages and rising prices are making life more difficult for building owners and engineers. In light of these constraints, Cortec’s MCI®-2020 technology has become an especially important resource for value engineering at this time.

Dealing with Silane Shortages

One of the big issues engineers and building owners have recently had to deal with is a shortage of silane. Supplies are more difficult to find and more expensive. This is a big obstacle for the construction and building maintenance industry, which has typically relied on silane products for concrete water-repellency. Silane is used to limit the ingress of corrosives and is often applied during routine maintenance or at the end of a concrete repair. Contractors currently either have to swallow a higher price for the limited silane available or find other ways to protect structures from corrosion.

An excellent alternative is MCI®-2020, a Migrating Corrosion Inhibitor™ surface treatment designed to penetrate through cementitious materials including concrete, mortar, and limestone. It provides corrosion protection against carbonation, chlorides, and other contaminants. Although it does not include water repellency like some other surface applied corrosion inhibitors (SACIs), it introduces a stronger concentration of Migrating Corrosion Inhibitor™ to reduce corrosion rates of rusted rebar in concrete. By itself, this can have a powerful impact on the longevity of the building. However, MCI®-2020 can also be followed by any water-repellent or coating system to maximize and even enhance concrete corrosion protection in the wake of silane shortages.

Reducing Time and Labor Costs

Another reason MCI®-2020 is an important resource for value engineering is its overall cost- and labor reducing characteristics compared to other methods of corrosion protection for existing structures. For example, installing sacrificial anodes is a common method of protecting corrosion “hot spots” when performing concrete repairs. The technology works, but only if the rebar has a continuous connection to the anode. Installation is time- and labor-intensive, requiring workers to drill or chip out parts of the concrete in order to install hundreds or thousands of anodes for a typical job. To make matters worse, anodes become depleted over time and often have to be reinstalled within 10 years, requiring more excavation and repair of the concrete cover.

In contrast, MCI®-2020 is easy to apply by spray, brush, or roller to a clean concrete surface in one to two coats. It also happens to be one of the easiest SACI products on the market to apply and has the highest concentration of corrosion inhibitor. Unlike most other SACIs, MCI®-2020 requires fewer coats and less wait time between coats. It is also easier to clean (e.g., water rinse only) before applying a topical treatment (e.g., coating, water repellent, membrane system) on top.

Mitigating Corrosion on Buildings with Façades

In spite of MCI®-2020’s superior advantages over other concrete corrosion inhibitor solutions, some architecture demands still other value engineering solutions. This is the case with concrete buildings covered by tiling, stone cladding, paint, or other façades that make it difficult if not impossible to apply the SACI to the surface without time consuming and cost-prohibitive façade removal. MCI®-2020 Gel allows engineers and repair workers to inject the corrosion inhibitor to the depth of the rebar by drilling inconspicuous holes at routine intervals. While this process is similar to applying anodes, it is much simpler because it is not necessary to make a direct connection from an anode to the reinforcing steel. The most important advantage, however, is the cost and labor savings from not having to do major deconstruction of the exterior wall in order to apply Migrating Corrosion Inhibitors.

Leveraging Cost-Effective Materials for High Level Returns

In today’s market, specifying engineers and other decision makers must be especially creative and adept at leveraging cost-effective materials and strategies for high level returns on structural safety, longevity, and sustainability. When it comes to mitigating corrosion to extend the service life of existing concrete structures, Cortec® MCI®-2020 and MCI®-2020 Gel offer excellent value for cost. Contact Cortec® MCI® today to discuss these and other value engineering solutions: https://www.cortecmci.com/contact-us/

Keywords: value engineering, cutting costs, extend service life, silane shortages, surface treatment, concrete repairs, corrosion protection, sacrificial anodes, Cortec MCI, From Grey to Green

Need a High-Resolution Photo? Visit: www.cortecadvertising.com

For a PDF version please click here.

NEWS ALERT: Seven New DOT Approvals for Cortec® MCI®!

August 9, 2022

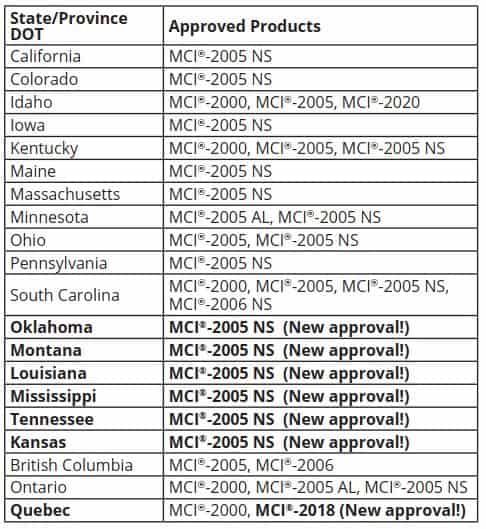

Cortec® is excited to announce seven new DOT approvals for MCI® Technology in North America! In the U.S., six more state DOTs have added MCI®-2005 NS to their list of approved concrete admixtures. In Quebec, Canada, MCI®-2018 has been approved for DOT use in addition to previously approved MCI®-2000. DOT approval is important for three reasons:

- It allows engineers to specify MCI® in DOT construction projects for these states/provinces.

- It lends credibility to engineers desiring to use MCI® Technologies in non-DOT projects.

- It ultimately can improve the quality of construction by qualifying good-performing products through rigorous review according to industry standards.

MCI®-2005 NS is a concrete admixture that delays time to corrosion and reduces corrosion rates once started. MCI®-2018 is a surface applied corrosion inhibitor (SACI) with water repellency that can be used for periodic maintenance or concrete repair.

With 42% of all U.S. bridges at least 50 years old (according to the 2021 Report Card for America’s Infrastructure*), today’s generation is seeing a greater need to extend service life for both new and existing structures. MCI® is one of the easiest and most cost effective ways to do so, especially in coastal regions or states/provinces where harsh winters require the use of deicing salts. In addition, MCI® can be helpful in any region to combat carbonation-induced corrosion that sets in over a long period of time.

The following 20 states/provinces have DOT approvals for MCI® in one or multiple forms.

Cortec® continues to work on the DOT approval application process in other states and looks forward to extending the regions where MCI® can be used in DOT projects. In the meantime, we encourage you to take advantage of the many DOT approvals already in existence to promote greater longevity of bridges and other reinforced concrete structures across North America!

Contact Cortec® MCI® for more info: https://www.cortecmci.com/contact-us/

Keywords: concrete admixtures, concrete repair, corrosion inhibitors, concrete corrosion, Cortec MCI, From Grey to Green, DOT approvals, SACI, extend service life, longevity of bridges

*See https://infrastructurereportcard.org/cat-item/bridges/.

For a PDF version please click here.

Cortec-Coated Croatian Bridge Opens to Traffic Featured in Paint & Square Magazine

NEWS ALERT: Using MCI® to Enhance Sustainability of Concrete Oil and Gas Structures

August 4, 2022

Regardless of the current impetus toward “greener” energy, it remains a fact that society is heavily dependent on the oil and gas industry and will likely remain so in the near future. This does not mean nothing can be done to improve the sustainability of existing oil and gas infrastructure. One great strategy for doing so is to extend the service life of reinforced concrete structures using Cortec® MCI®.

Taking Concrete From Grey to Green™

MCI® Technology extends concrete service life by mitigating corrosion on embedded reinforcing metal. Corrosion is one of the chief enemies of concrete longevity because it leads to cracking, spalling, and eventual deterioration of the structure. Since concrete production is such an energy intensive activity, helping concrete last longer is an important part of a sustainability-savvy and resource efficient society. The less often that concrete repairs or replacements have to be made, the more resources are saved, and the smaller the concrete carbon footprint becomes.

Vulnerable Oil & Gas Structures

There are many different concrete structures to consider in the oil and gas industry, with some at greater risk for corrosion than others. For example, many oil and gas terminals are located in coastal environments or harsh regions of the Middle East where airborne chlorides, heat, humidity, or even soil minerals can be highly corrosive. Many fixed or floating offshore platforms, terminals, foundations, and caissons are also made of reinforced concrete exposed directly to high-chloride seawater. These factors can seriously decrease the service life of concrete structures if special measures are not taken to counteract corrosion. Among these measures, a high-performance concrete design mix, preventative maintenance, and quality repairs are of utmost importance.

When to Use MCI®

The best time to apply MCI® is as a concrete admixture (MCI®-2005 or MCI®-2005 NS) in new cast-in-place structures or precast concrete elements. MCI® molecules form a protective layer on the surface of the reinforcing metal that delays time to corrosion and reduces corrosion rates once started. However, even existing structures can benefit from MCI®. CorrVerter® MCI® Rust Primer is an excellent option for prepping exposed rusted rebar during concrete repairs. Surface applied corrosion inhibitors (SACI) such as MCI®– 2019 (MCI® + water repellent) or MCI®-2020 (MCI® only) are excellent additions to enhance the lifetime of the repair or to apply simply for periodic maintenance on oil and gas structures. These MCI® SACIs migrate through the concrete pores to reach and protect embedded reinforcement. MCI®-2061 is a complementary biological-based cleaner that uses biodegradable surfactants and microorganisms to remove oil stains before the application of a SACI, a coating, or a membrane system.

Take Responsibility for Critical Resource Stewardship

The oil and gas industry is part of today’s existing critical infrastructure that demands responsible stewardship. By taking basic steps like using MCI® Technology to extend service life—particularly for at-risk structures in corrosive environments—the oil and gas industry can save time and money while indirectly reducing their carbon footprint. Contact Cortec® for further assistance in finding ways to enhance the sustainability of concrete oil and gas industry

structures: https://www.cortecmci.com/contact-us/

Keywords: sustainability, concrete oil and gas structures, MCI, From Grey to Green, extend service life, mitigating corrosion, concrete admixture,

Cortec, rusted rebar, reduce carbon footprint

For a PDF version please click here.

Grand Opening of Peljesac Bridge in Croatia Featured in PIM Magazine

PRESS RELEASE: Value Engineering Meets Sustainability with MCI® Technology for Concrete

August 4, 2022

In this day and age of inflation, supply chain delays, and raw material shortages, value engineering is becoming more and more important as a way to cope with out-of control market factors. Construction industry engineers are looking for alternative materials to compensate for shortages and higher prices.

At the same time, there is increasing concern about being safe, extending service life, and enhancing sustainability. How do engineers meet these demands while staying sane and within budget? Migrating Corrosion Inhibitor™ (MCI®) Technology is an excellent answer for maximizing sustainability and service life while balancing cost considerations in these unpredictable times.

Extend Service Life at a Fraction of Total Cost

When it comes to construction, engineers can enhance sustainability by extending the service life of new concrete structures. This reduces the need to replace existing concrete, thus minimizing carbon output since cement production is a large contributor to global greenhouse gas emissions. Corrosion inhibiting admixtures are one way to enhance longevity from the start of a project by counteracting the deteriorating effect of carbonation, chlorides, and corrosives that cause rusted rebar in concrete. For example, MCI®– 2005 and MCI®-2005 NS are two MCI® concrete admixtures that delay time to corrosion and reduce corrosion rates once started by forming a molecular protective layer on the rebar surface. This is especially important where exposure to seaside environments, winter deicing salts, and sabkha soil is expected. It can also be important as a structure ages and carbonation sets in, reducing the naturally protective high alkalinity of the concrete.

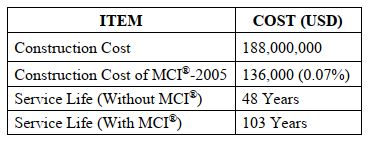

It is further important to note that MCI®-2005 and MCI®-2005 NS can significantly increase the

estimated service life of a structure at a small fraction of total construction costs. For example, one service life prediction estimated that using MCI®-2005 in the podium substructure of the Princess Tower in Dubai would extend service life from 48 years to 103 years. This was at 0.07% of the total construction cost.

MCI® Technology vs. Calcium Nitrite

MCI®-2005 and MCI®-2005 NS also have advantages when compared to other strategies of corrosion mitigation. For instance, they are great alternatives to

calcium nitrite (CNI) admixtures, the go-to corrosion inhibiting admixtures for decades. Some of the advantages of MCI®-2005 and MCI®-2005 NS are that they contain renewable materials, do not accelerate set time, have a fixed dosage rate, and are certified to meet NSF Standard 61 for use in potable water structures. In contrast, CNI is an inorganic, non-biobased chemistry that can be difficult for ready-mixers because it works as a set accelerator. It is not certified to meet NSF Standard 61, and it requires a higher dosage rate that increases based on expected chloride loading. It is not effective against carbonation corrosion.

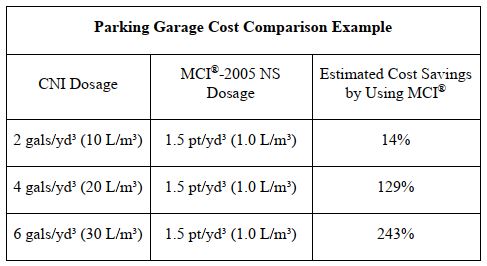

At first glance, CNI appears to be less expensive than MCI® due to a lower price per gallon. However, the true cost is hidden behind the dosage rate, which can be 2.0 or more gallons per cubic yard (10 L/m³), depending on expected chloride loading. MCI®–

At first glance, CNI appears to be less expensive than MCI® due to a lower price per gallon. However, the true cost is hidden behind the dosage rate, which can be 2.0 or more gallons per cubic yard (10 L/m³), depending on expected chloride loading. MCI®–

2005/2005 NS is more economical than CNI in almost all cases because it is dosed at a fixed rate of 1.0-1.5 pints per cubic yard (0.6-1.0 L/m³). A recent parking garage project brings this cost comparison into focus. The garage required enough admixture for 20,000 cubic yards (15,291 m³) of concrete. The estimated cost savings by using MCI® was 14% when compared with the price of CNI dosed at 2.0 gallons per cubic yard (10 L/m³). At higher dosages (e.g., 4.0-6.0 gallons per cubic yard [20-30 L/m³]), the cost savings would have soared to between 129% and 243%. Furthermore, the use of CNI may require a higher dose of air-entraining agents or the addition of set-retarding or shrinkage-compensating admixtures. This is not required when using MCI®, making room for additional savings.

MCI® Technology vs. Epoxy Coated Rebar

Another common strategy to mitigate corrosion and extend service life is to use epoxy coated reinforcing steel. The major challenges are high cost and vulnerability to corrosion where the epoxy coating has chipped. Interestingly, MCI® can offer substantial cost savings and service life advantages. For example, the recently constructed Lodge at Gulf State Park was initially specified to use epoxy coated rebar. However, due to budget constraints and a better service life prediction with MCI®, the specifying engineer ultimately settled on MCI®-2005 admixture instead. As a result, the project saved six figures and incorporated a biobased product that could help earn credit toward LEED certification.

Value Engineering with MCI®

The comparative advantage goes on. Some designers have used MCI® to reduce the concrete cover requirements while achieving the same service life estimates, which consequently allowed them to reduce the amount of steel reinforcement to control concrete cracks. In some cases, this allowed for a seven-figure savings in the total cost of the project. The important point is that, by evaluating MCI® next to other materials and strategies, engineers can find the best cost benefit ratio for their structures in the construction, repair, and maintenance phases. Contact Cortec® for an MCI®/CNI cost comparison and more strategic ideas on value engineering with MCI®: https://www.cortecmci.com/contact-us/

Keywords: value engineering, sustainability, MCI, concrete admixtures, rusted rebar in concrete, extend service life, increasing inflation, raw material shortage, From Grey to Green, Cortec

Need a High-Resolution Photo? Visit: www.cortecadvertising.com

For a PDF version please click here.