PRESS RELEASE: MCI®-2026 Primer WB for Concrete: A Great Alternative to Solvent-Based Sealers!

August 2, 2022

The porous nature of concrete makes it very susceptible to moisture—whether seeping up from the ground beneath or penetrating down from wet materials on the surface above. UV light and chemicals can also damage the substrate and cause premature degradation. This makes sealers a basic element of proper concrete maintenance to extend service life in many circumstances. MCI®-2026 Primer WB is one excellent option to consider for sealing out moisture and protecting concrete, devoid of many disadvantages associated with a solvent-based sealer.

The porous nature of concrete makes it very susceptible to moisture—whether seeping up from the ground beneath or penetrating down from wet materials on the surface above. UV light and chemicals can also damage the substrate and cause premature degradation. This makes sealers a basic element of proper concrete maintenance to extend service life in many circumstances. MCI®-2026 Primer WB is one excellent option to consider for sealing out moisture and protecting concrete, devoid of many disadvantages associated with a solvent-based sealer.

MCI®-2026 Primer WB is a 2K (two-component) 52% solids water-based epoxy coating system that outperforms and outlasts most solvent-based sealer systems without the associated odors, flammability, or VOCs. MCI®-2026 Concrete Primer WB offers good moisture and chemical resistance. The low viscosity allows for greater substrate penetration, improved handling, and easier application, while the lack of solvent odors makes MCI®-2026 Primer WB inoffensive during indoor applications. Compared to traditional concrete sealers, it is more durable, and cleanup is much easier after application. MCI®-2026 Concrete Primer has excellent adhesion and dries quickly in one to three hours before it can be recoated. At <60 g/L VOC per EPA Method 24, it is compliant to all VOC/HAPS regulations. It meets all of the USDA/FDA guidelines for use in federally inspected facilities.

MCI®-2026 Concrete Primer WB works great independently as a standalone concrete sealer and is an economical alternative to its 100% solids novolac epoxy coating counterpart. For extra durability, MCI®-2026 Concrete Primer WB can be applied in two coats, creating a tough concrete sealer system for heavy (rolling) traffic. Those that are willing to make the investment will find MCI®– 2026 Primer WB to be a great companion to MCI®-2026 Floor Coating as a base primer in situations where extra resistance to moisture from the concrete is needed. The end result is an extra tough barrier to moisture, chemicals, and physical abrasion.

MCI®-2026 Concrete Primer WB comes in clear or grey to provide an inconspicuous and/or fresh appearance in industrial settings. This is great for use in factories, garages, food processing facilities, and many other industrial environments where there is frequent spillage, cleaning, cart or vehicle traffic, and residual oils or greases.

Possible applications include

• Garage floors

• Food processing facility floors

• Shop/factory floors

• Chemical and pharmaceutical industry floors

• Laboratory floors

• Decorative concrete overlays

One of the most basic forms of concrete protection is to seal out the elements. MCI®-2026 Primer WB does so without the cost of a full heavy-duty epoxy system and without the nuisances of a solvent-based system. For economical, worker-friendly, industrial-strength protection, contact Cortec® to learn more about using MCI®-2026 Primer WB: https://www.cortecmci.com/contact-us/

Keywords: concrete sealers, Cortec MCI, MCI, concrete primer, floor coating, epoxy coating, proper concrete maintenance, alternative to solvent based sealers, protecting concrete, extend concrete service life

Need a High-Resolution Photo? Visit: www.cortecadvertising.com

For a PDF version please click here.

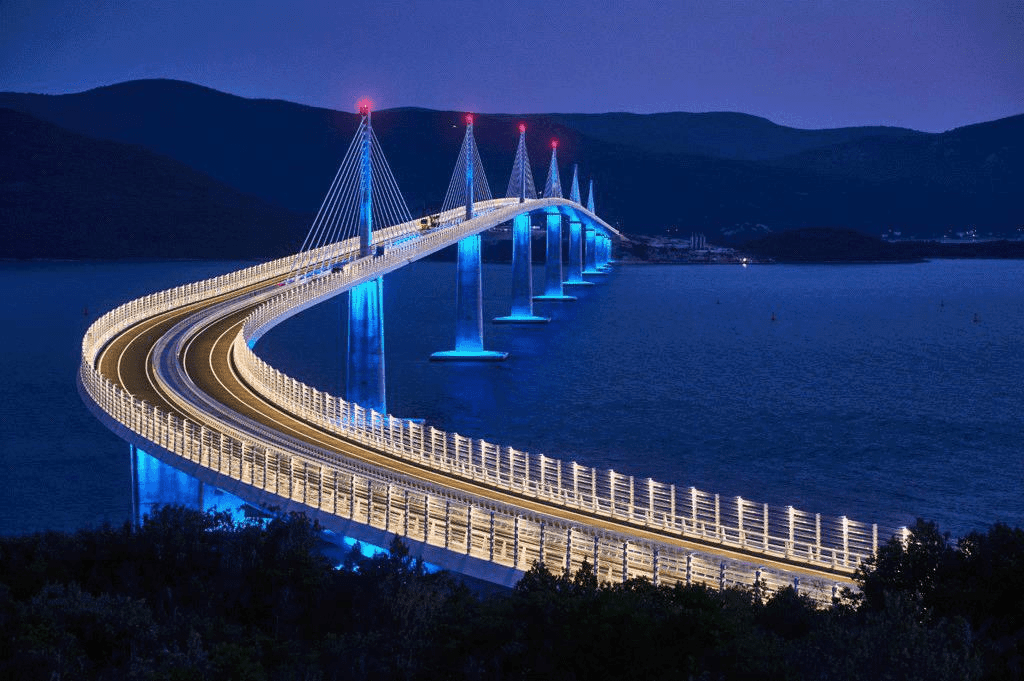

PRESS RELEASE: Grand Opening of Peljesac Bridge in Croatia: MCI® Technology Applied on One of the World’s Most Demanding Construction Projects!

August 2, 2022

On 26 of July, Pelješac Bridge, the largest ever EU infrastructure investment in Croatia, officially opened in grand ceremony. The bridge, providing a road link between two parts of the country is of strategic importance and is one of the most substantial EU infrastructural investments ever. It connects the region of Southern Dalmatia with the rest of the country’s mainland. The bridge will cut travel time by 37 minutes along the Adriatic coastline, improving people’s lives and increasing economic opportunities for the region. It has 13 spans, five of which are 285 meters long, six centrally placed reinforced concrete pylons with a height of 33 meters, and two lanes together with a stop lane that will serve for bridge maintenance.

Peljesac bridge is ranking among the most demanding bridges in the world—in complexity of construction and design. Bridge is 2,404-m (7,887.14-ft) long. ln order to meet the main criteria of quality design, such as stability, durability, economy and integration into the environment, the design proposed the construction of an extra dosed bridge with an integrated hybrid structure. Structure is comprised of five central spans, each 285-m long, and six low pylons. Especially careful approach was taken to ensure durability for the extended lifespan of over 130 years. Cortec’s MCI® 2018 was specified on this project during the design phase as a silane-based impregnation with a migrating inhibitor property to protect against the harmful effects of corrosion, thus extending the service life of the bridge. MCI® 2018 is a 100% silane-based concrete sealer, containing migrating corrosion inhibitors that allow deep penetration into concrete and provides water repellence by chemically reacting with the cementitious substrate. It seals surface pores, preventing the intrusion of chlorides, reduces carbonation, and protects from the ingress of wind-driven rain. Treated concrete surfaces are fully breathable and their natural moisture-vapor transmission is not affected. After repair of surface damage and cleaning of discolorations and other surface defects, the concrete surface of the pylons needed to be protected with a colorless silane coating to improve durability and increase the resistance of the concrete surface to long-term external influences. MCI®-2018 carries CE certification that indicates conformity with health, safety and environmental protection standards for products sold within the European Economic Area (EEA).

Application of Cortec’s MCI®-2018

A combination of AC coatings, cathodic protection of steel reinforcement in piles and pile heads, a concrete cover of 65–85 mm stainless steel reinforcement and impregnation of all concrete surfaces with MCI®-2018 was selected. This was chosen as the strategy to help the bridge achieve a 130-year service life. MCI®-2018 was applied on the entire substructure of the bridge. All concrete parts were coated with MCI®-2018 by a spraying technique. The work was performed in accordance with the project requirements and after surface preparation to full functionality. This included:

- Access to pylons

- Rehabilitation of the concrete surface of the pylons

- Cleaning the concrete surface of the pylon (washing the pillars with water)

- Impregnation of the concrete surface of the pylon with MCI®-2018.

MCI®-2018 contains time-proven Migrating Corrosion Inhibitors (MCI®). The silane component provides water repellency by chemically reacting with the cementitious substrate under proper application, decreasing the ingress of aggressive materials. The product penetrates deep into concrete, providing corrosion protection to reinforcing steel from existing water and chloride ions, or other contaminants. Continuous monitoring of the condition of the structure at one central place was done during the construction phase and will be done at the exploitation phase to examine parameters of structural behavior, time, seismic activity, and structural durability. The designer of the bridge specified corrosion protection for all concrete segments in order to achieve a 130-year service life.

Cortec’s CEO, Boris Miksic, Croatian-American businessman is proud that his patented technology was used on this historic project to connect two parts of his country. “Our MCI® technology is used in largest construction projects throughout the globe. Witnessing its application in my home country on this monumental bridge structure is truly a special. Peljesac bridge is huge step forward for all of us.” A strategic investment such as this bridge, demonstrates European Commission’s commitment to bring people together and unite territories, while reinforcing the territorial cohesion of the region and helping other neighboring countries.

You can learn more about Migrating Corrosion Inhibitors (MCI®) here: https://www.cortecmci.com/

Need a High-Resolution Photo? Visit: www.cortecadvertising.com

For a PDF version please click here.

Reduce Your Concrete Carbon Footprint While Enhancing Concrete Durability Featured in NED Magazine

How to Avoid Mud Cracking When Applying Anticorrosion Coatings Featured in CRB Magazine

Interview With Cortec® Corporation Featured in Easy Engineering Magazine

Pre-packaged corrosion inhibitor Featured in Concrete Products Magazine

PRESS RELEASE: Cortec® Launches New Improved MCI®-2039 Horizontal Concrete Repair Mortar!

June 21, 2022

In a world where concrete is the most widely used construction material, the need for concrete repairs is inevitable. This is especially true in corrosive environments where concrete deterioration accelerates due to seawater or heavy use of deicing salts. Since concrete repairs are time and labor intensive, it is important to do them in a way that will extend structural service life as much as possible. Cortec’s new, improved line of MCI® repair mortars is designed to help contractors reach that goal, starting with the release of MCI®-2039 High Performance Horizontal Repair Mortar.

Enhance Repairs with Migrating Corrosion Inhibitors

MCI®-2039 is a single-component, fast-setting, high-strength, cement-based repair mortar enhanced with Migrating Corrosion Inhibitors (MCI®). These inhibitors form a molecular protective layer on the surfaces of rebar, increasing the quality and extending the service life of the repair and surrounding structure. Once applied and hardened, MCI®-2039 provides a high level of adhesion and durability, as well as resistance to water and carbonation attack. High early strength allows for fast repairs and quick return of traffic. MCI®-2039 can be applied indoors or outdoors in a wide temperature range, from 20 to 100 °F (-6 to 38 °C). The mortar can be extended up to 60% by weight for repairs greater than 2” (51 mm) deep.

Minimize the Ring-Anode/Halo Effect

One major problem with concrete repairs is the insidious ring-anode/halo effect. This occurs when the higher pH and resistivity of the patch material creates a difference in corrosion potential between new and old concrete. As a result, corrosion activity may accelerate in the concrete surrounding the patch. What was intended to fix the problem inadvertently shifts the corrosion process to another area. MCI®-2039 can minimize this counterproductive effect as Migrating Corrosion Inhibitors in the repair mortar travel to adjacent concrete to even out the corrosion potential and help the repair last longer.

Implement a High Performance Repair System (HPRS®)

MCI®-2039 is part of Cortec’s MCI® High Performance Repair System (HPRS®), which outlines five steps to achieve long-lasting concrete repairs. The first step is to prepare the substrate following ICRI Guideline No. 310.2R-2013 (or a similar engineering guide). Secondly, rusty rebar should either be blasted to bright metal or coated with CorrVerter® MCI® Rust Primer to passivate the rust. MCI®-2039 is applied next (for horizontal repairs). After the repair mortar has cured, a surface applied corrosion inhibitor (SACI) such as MCI®-2020 (or a water-repellent MCI® SACI) should be used on the entire concrete surface. An optional final coat of MCI® EcoRainbow® Architectural Coating protects against water intrusion and carbonation and provides a finished look.

By following these MCI® HPRS® guidelines, concrete contractors can maximize the durability of the patch and thus delay time to the next repair, substituting MCI®-2039 for standard repair mortar to enhance protection wherever a horizontal concrete repair is needed:

- Bridge decks, parking decks, and ramps

- Highway repairs and overlays

- Slabs below grade, on grade, or above grade

- Loading docks

- Airport runways

- Industrial and commercial structures

Make Repairs Last Longer with MCI®-2039

For anyone looking to enhance the longevity of a concrete repair, MCI®-2039 is a convenient way to add corrosion protection directly into the repair process. Combined with the entire MCI® HPRS®, it is an even more powerful antidote to corrosion decay in reinforced concrete. Contact Cortec® MCI® today to learn about MCI®-2039 and other MCI® enhanced repair products: https://www.cortecmci.com/contact-us/

To learn more about MCI®-2039, please visit: https://www.cortecmci.com/product/mci-2039/

Keywords: concrete repair, concrete contractors, corrosion inhibitors, repair mortars, ring anode effect, Cortec MCI, From Grey to Green, make repairs last longer, SACI, surface applied corrosion inhibitors

For a PDF version please click here.