CASE HISTORY #734: The Mercantile Parking Garage: Building for 100-Year Service Life

FEATURED IN: Preventing Collapsing Structures Featured in ISSUU Magazine!

Earn AIA Learning Units with Cortec® MCI®!

August 25, 2021

Cortec® continues to reinforce its position as a global leader in corrosion control solutions by offering educational courses designed for the construction industry. As part of this initiative, Cortec® has recently registered and been approved as a “passport” level continuing education system provider (CES) with the American Institute of Architects (AIA)!

Cortec® has always been keen on providing educational services to construction professionals regarding corrosion inhibitors and the role they play in improving the durability of concrete and steel structures. Cortec’s presentations and educational offerings have generally been delivered in a variety of formats and venues including “Lunch and Learns,” individual meetings, virtual seminars, industry events and trade shows, and more. To add even more value to these opportunities, Cortec’s presentations now earn attendees education credits that can be used toward renewing individual professional registration licenses in different jurisdictions. Cortec’s accredited educational content will be available in person, online, live, or on demand anywhere in the world.

Currently registered Cortec® MCI® courses offer participants elective learning units and Health, Safety, and Welfare (HSW) learning units.

The courses primarily discuss the corrosion challenges in construction and the role of corrosion inhibitors in mitigating these problems. The following topics are among the offered courses:

• How corrosion happens in concrete

• Service life modeling to predict the serviceability of a concrete structure

• An introduction to corrosion inhibitors including their types, mechanisms, applications, and limitations

• Testing and verification of corrosion inhibitor performance

• Global case histories where corrosion inhibitors have been used successfully

Registered courses are being offered to all construction professionals and can be requested on the Cortec® MCI® website at this link: https://www.

cortecmci.com/aia-ces-continuing-education-programs/. Apply today!

Keywords: AIA, continuing education, MCI, Migrating Corrosion Inhibitors, service life, corrosion, corrosion protection, construction,

corrosion in concrete, architects, durability

For a PDF version please click here.

How Do MCI®-2005/2005 NS Admixtures Compare to the Competition?

August 19, 2021

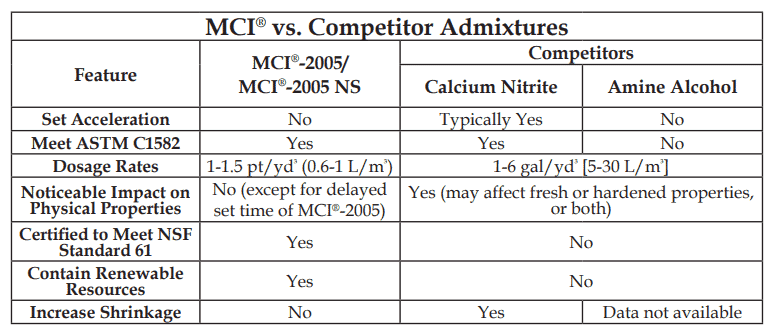

When building new concrete structures, ready mix suppliers, project owners, and specifying engineers naturally want to use the product that works best for the job. So, in the case of corrosion inhibitors, what are the defining features of how MCI® admixtures line up against the competition? Here are some key factors to know when comparing MCI®-2005 and MCI®-2005 NS amine carboxylates against other corrosion inhibiting admixtures on the market.

• MCI®-2005/2005 NS do not accelerate set time. Calcium nitrite typically does, sometimes to great disadvantage by decreasing workability and increasing cold joint formation.

• MCI®-2005/2005 NS meet ASTM C1582. Amine alcohol corrosion inhibiting admixtures do not.

• MCI®-2005/2005 NS have small dosage rates compared to calcium nitrite and competitor amine alcohols (MCI®: 1-1.5 pt/yd³ [0.6-1 L/m³]; Competition: 1-6 gal/yd³ [5-30 L/m³]).

• MCI®-2005 NS has no noticeable impacts on concrete physical properties including compressive strength, set time, and air content, unlike competing corrosion inhibitors. (MCI®-2005 slightly delays set time, which is often desired.)

• MCI®-2005/2005 NS are certified to meet NSF Standard 61 for use in potable water structures. Competitor technologies are not.

• MCI®-2005/2005 NS contain renewable resources (MCI®- 2005 in particular is a USDA Certified Biobased Product). Calcium nitrite admixtures do not.

• MCI®-2005/2005 NS do not increase shrinkage compared to a control. Calcium nitrite admixtures can have serious problems with shrinkage cracking.

Each of these qualities carries important implications for the builder and can affect workability, sustainability, or even long-term durability, all of which typically translate into economic savings.MCI®-2005/2005 NS admixtures come out of the comparison with obvious advantages.

Log in to the rep section of our MCI® website to access more specific competitor comparisons soon:

https://www.cortecmci.com/login/

Keywords: corrosion, concrete, admixtures, Migrating Corrosion Inhibitors, MCI, cold joints, durability, service life, construction, ready mix, specifying engineers, rebar corrosion, concrete, admixture.

For a PDF version please click here.

MCI-2020 Gel Delivers Robust Corrosion Protection to the Depth of Steel Reinforcement

August 24, 2021

Corrosion of metal reinforcement is one of the most serious threats to the durability of concrete structures. While many excellent technologies delay and mitigate the effects of corrosion on embedded reinforcement, there are fewer options when corrosion takes place deep inside concrete. Is such difficult-to-access corrosion beyond the reach of existing treatments? Cortec® Corporation answers that question with a resounding “no!” in the form of MCI®-2020 Gel, designed to penetrate to the heart of a structure’s corrosion problem.

MCI®-2020 Gel is an injectable corrosion inhibitor which provides a robust dose of corrosion protection directly at or near the depth of steel reinforcement in concrete. MCI®-2020 Gel utilizes the time-proven chemistry of Cortec’s Migrating Corrosion Inhibitor™ (MCI®) Technology to migrate to steel reinforcement from injection locations. Once at the reinforcing steel, MCI® molecules deposit across the metal surface to form a molecular layer which acts as a barrier to corrosive elements such as chlorides. This technology has many advantages:

MCI®-2020 Gel is an injectable corrosion inhibitor which provides a robust dose of corrosion protection directly at or near the depth of steel reinforcement in concrete. MCI®-2020 Gel utilizes the time-proven chemistry of Cortec’s Migrating Corrosion Inhibitor™ (MCI®) Technology to migrate to steel reinforcement from injection locations. Once at the reinforcing steel, MCI® molecules deposit across the metal surface to form a molecular layer which acts as a barrier to corrosive elements such as chlorides. This technology has many advantages:

• Targeted application: MCI®-2020 Gel can be applied at customizable depths to meet the needs of a structure, directly targeting problem locations and reducing time needed for migration of the inhibitor

• Minimally invasive: Injection holes can be drilled smaller than for comparable products in many cases

• Economical to install and maintain: Holes can be capped for easy reapplication or sealed with repair mortar as desired

• Attractive safety benefits: MCI®-2020 Gel is non-flammable, non-combustible, and does not contain secondary amines or nitrites (which together can form carcinogenic nitrosamines).

There are many situations where MCI®-2020 Gel provides a welcome solution because of the difficulty of transporting corrosion inhibitors to the level of the rebar. For example, structures with inconsistent or thick concrete cover or multiple layers of reinforcing steel will require protection beyond the reach of topical treatments. Structures with sealers or tile facades present a physical barrier to the application of a surface applied corrosion inhibitor (SACI) and also need a different approach. MCI®-2020 Gel penetrates beyond these obstacles to deliver corrosion protection to the depth required. Suggested applications where this may be needed include

• Below grade tunnels

• Window lintels

• Buildings with facades

• Residential buildings

• Structural walls and equipment bases

• Parking decks, ramps, and garages

• Marine structures, dams, or piers

• Balconies, decks, retaining walls, and lanais

Corrosion of concrete reinforcement is an insidious problem that ultimately reveals itself in cracking and deteriorating structures. Arresting corrosion at the root level before it proceeds too far can be difficult but no longer impossible in hard-to-access locations thanks to MCI®-2020 Gel. Contact Cortec® to discuss how it could apply to your own deep-seated corrosion issue: https://www.cortecmci.com/contact-us/

Learn more about MCI®-2020 Gel here: https://www.cortecmci.com/product/mci-2020-gel/

Keywords: concrete, corrosion, spalling, rebar corrosion, service life, concrete repair, concrete maintenance, Migrating Corrosion Inhibitors, MCI, Cortec, structural durability, SACI

For a PDF version please click here.

MCI®-2005 NS Admixture Recently Approved by Three New DOTs!

August 17, 2021

MCI®-2005 NS corrosion inhibiting admixture has recently been approved for DOT use in three more states! This is exciting news for engineers in Pennsylvania, Maine, and Massachusetts who can now specify an industry leading admixture in their concrete design mixes for new construction and repair of roads, bridges, and other public transportation infrastructure. MCI® is one of

the easiest and most cost-effective ways to build a longer service life into a new or existing structure and hence can have beneficial ripple effects on budget and safety concerns long-term.

Corrosion: A Serious Threat to Infrastructure

According to the 2021 Report Card for America’s Infrastructure,* 42 out of every 100

bridges in the U.S. are 50 years old or more and 7.5% are in “poor” condition, meaning ongoing

repair will be needed for years to come. As new projects develop, engineers will likely place an

increasing focus on building structures to last longer. One major threat to extended service life is corrosion of embedded reinforcing metal in concrete that eventually cracks and pushes away the concrete cover, causing the structure to deteriorate. Migrating Corrosion Inhibitor™ Technology mitigates this problem by delaying corrosion onset and reducing corrosion rates once started.

Normal Set MCI® Admixture

MCI®-2005 NS is one of Cortec’s most popular normal-set water-based organic corrosion inhibiting admixtures. It meets all requirements of ASTM C1582. When incorporated into concrete, MCI®-2005 NS forms a protective molecular layer on embedded metals to inhibit corrosion. In new

construction, this is quantified by an increase in critical chloride threshold and subsequent reduction in corrosion rates after corrosion initiates. When used with repair mortars and grouts, MCI®-2005 NS not only protects rebar within the patch; it is able to migrate into undisturbed concrete adjacent to the repair to protect reinforcement already in place. Unlike traditional calcium nitrite (CNI) admixtures, MCI®- 2005 NS admixture can be dosed independently of expected chloride loading and does not accelerate set time—a critical factor for finishing crews, especially in hot weather.

DOT Approvals in North America

DOT approvals not only expand the potential reach of where MCI® can be used for transportation infrastructure; they also lend credibility for use in projects that do not require DOT approval (e.g., parking garages). In addition to the recent acceptance of MCI®-2005 NS by MaineDOT, MassDOT, and PennDOT, MCI® Technology/admixtures have been approved in a variety of other states and provinces over the years.

These include

• British Colombia (MCI®-2005, MCI®-2006)

• California (MCI®-2005 NS)

• Colorado (MCI®-2005 NS)

• Idaho (MCI®-2000, MCI®-2005, MCI®-2020)

• Iowa (MCI®-2005 NS)

• Kentucky (MCI®-2000, MCI®-2005, MCI®-2005 NS)

• Maine (MCI®-2005 NS) – New approval!

• Massachusetts (MCI®-2005 NS) – New approval!

• Minnesota (MCI®-2005 AL, MCI®-2005 NS)

• Nebraska (MCI®-2020)

• Ohio (MCI®-2005, MCI®-2005 NS)

• Ontario (MCI®-2000, MCI®-2005 NS, MCI®-2005 AL)

• Pennsylvania (MCI®-2005 NS) – New approval!

• Quebec (MCI®-2000)

• South Carolina (MCI®-2000, MCI®-2005, MCI®-2005 NS, MCI®-2006 NS)

Of special note are states/provinces known for harsh winters (high use of deicing salt) or coastal environments, both of which take a heavy toll on reinforced concrete structures and require strategic anti-corrosion planning. Since application processes and renewal requirements vary by state, engineers should check each DOT’s qualified product list for the most up to date information and new developments before starting a project. Meanwhile, the expansion of MCI® DOT approvals to three more states is an exciting opportunity for engineers to take advantage of one of the best, most cost-effective and easy to work with corrosion inhibiting technologies on the market!

Contact Cortec® MCI® to learn more: https://www.cortecmci.com/contact-us/

*See https://infrastructurereportcard.org/cat-item/bridges/

For a PDF version please click here.

NEWS ALERT: Fun and Fundraising for a ‘Concrete’ Cause

August 10, 2021

The Cortec® MCI® team had fun July 20th playing golf and raising money for a good cause at the ICRI (International Concrete Repair Institute) Minnesota Chapter Annual Golf Tournament at Bunker Hills Golf Course. The yearly event is a fundraiser for the ICRI scholarship that goes to a student taking courses related to concrete repair, whether it be in engineering or a related trade.

Jessi Meyer (VP of Sales) and Lisa Marston (Technical Service Engineer) made up a foursome with a readymix supplier client from AVR, while Jon Connealy (Regional Sales Manager – MCI® Central) worked at the hole sponsored by Cortec®. Jon hosted golf Skeeball and gave away small prizes for playing as well as rewarding the highest and lowest scores of the day. Cortec® also sponsored one of the evening’s prize drawings—a “Play Nine” golf card game and a pro shop gift certificate won by MN ICRI member Terry Babcock.In a day with increasing concern about repair maintenance of buildings, ICRI is truly the main go-to for information on the proper repair of concrete and masonry structures. Cortec® has been a proud supporter of this organization for over 20 years and was happy to promote education and concrete repair once again through the local ICRI chapter golf sponsorship!

Learn more about ICRI Minnesota here: https://www.icri.org/page/MIN_chapter

For a PDF version please click here.

Surface Applied Corrosion Inhibitors (SACIs): Comparing “Apples to Apples” vs. “Apples to Oranges”

August 10, 2021

When it comes to selecting Surface Applied Corrosion Inhibitors (SACIs) for concrete repair and maintenance, it is important for engineers to know how and why to compare “apples to apples” instead of “apples to oranges.” The International Concrete Repair Institute (ICRI) Technical Guideline No. 510.2-2019, “Guideline for Use of Penetrating Surface Applied Corrosion Inhibitors for Corrosion Mitigation of Reinforced Concrete Structures,” provides a good place to start. From there, Cortec® Corporation helps engineers sort through the many varieties of “produce” on the market to help engineers compare “apples to apples” instead of “apples to oranges” and pick the product best suited to the job.

Sorting Out “Apples from Oranges”

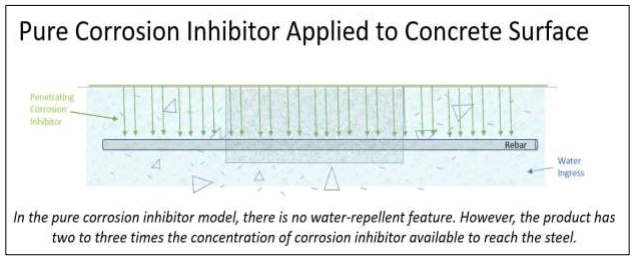

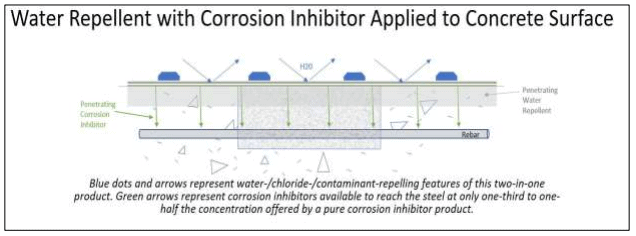

The ICRI guideline defines SACIs as liquids that penetrate concrete to the depth of embedded reinforcement and actively mitigate corrosion on the steel surface. These SACIs include amine-based corrosion inhibitors that travel in the vapor phase through the concrete pore structure and form a molecular protective layer on the rebar. Surface applied products that contain only water repellents do not qualify. Standard water repellents penetrate only millimeters into the concrete; SACIs must penetrate as much as several inches. Water repellents recognized in the ICRI document contain the addition of amine-based corrosion inhibitors that can penetrate deeper into the concrete to reach embedded reinforcing steel. The document also includes pure corrosion inhibitors (neat inhibitor in a solvent, generally water) that are not water repellents. The difference is also explained in the figures below.

Generally speaking, the amount of corrosion inhibitor is highest in pure SACI products, and lower in water-repellentbased SACIs (but these materials have the added water repellency feature that allows them to be used as a two-in-one material). Water-repellent SACIs generally have a corrosion inhibitor concentration ranging from 1-10%, depending on the manufacturer, whereas a pure corrosion inhibitor with no water repellent typically ranges from 15-25% corrosion inhibitor concentration. Engineers who want corrosion protection at the level of the rebar, with or without water repellency, must be able to tell the difference between these products in order to specify the ones that will provide the most effective protection to the embedded reinforcement on the structures they are working on.

Comparing “Apples to Apples” vs. “Apples to Oranges”

Once engineers understand the difference between individual SACI products for concrete surface applications, they will be ready to compare “apples to apples” materials for their specific scenario. For instance, parking structure and bridge repairs often include the application of a traffic deck membrane or other coatings that are impermeable to water, chlorides, and other contaminants, as part of a protective “system” that also requires active corrosion inhibitors beneath the coating. In this scenario, the specifier might consider using pure SACI versus water-repellent-based SACI in order to get more

penetrating corrosion inhibitor into the concrete while still protecting against ingress of contaminants with the topcoat system. In situations where a topcoat is not used, the specifier might prefer to recommend water repellent-based SACI as a two-in-one solution. Specifying “apples to apples” would mean selecting pure SACI products as alternatives to each other, or water-repellent-based SACIs as alternatives to each other. “Apples to oranges” would mean specifying the use of a pure SACI as an alternative to a water-repellent based SACI.

SACIs from Cortec® Corporation

Cortec® Corporation offers the following SACIs as part of its MCI® Technology line to extend concrete service life:

Full-Strength SACI, No Water Repellent

MCI®-2020 is a top-of-the line option for use where a pure, high concentration penetrating corrosion inhibitor is needed. It is also available as MCI®-2020 V/O (for vertical/overhead use) or MCI®-2020 Gel (for injection beneath surfaces that cannot be disturbed or properly prepared).

Two-in-One Water Repellent SACIs

• MCI®-2018 (100% silane)

• MCI®-2019 (40% silane)

• MCI®-2021 (silicate)

• MCI®-2022 (silane/siloxane blend)

Contact Cortec® MCI® to learn more: https://www.cortecmci.com/contact-us/

Follow us on LinkedIn for more in-depth articles on SACIs forthcoming!

https://www.linkedin.com/showcase/mci-migratingcorrosion-inhibitors-/posts/?feedView=articles

For a PDF version please click here.