August 17, 2022

Water and wastewater treatment facilities are part of the critical infrastructure that makes our lives better on a daily basis, but often does not get a second thought. Nevertheless, the longevity of these structures not only impacts our municipal budgets but can also affect our long-term carbon footprint, since concrete production is among the largest contributors to anthropogenic greenhouse gas emissions. Specifying Migrating Corrosion Inhibitors (MCI®) into the concrete structural design can promote a more sustainable future by reducing the need for early replacement of high carbon-cost, energy-intensive reinforced concrete in drinking water reservoirs, desalination plants, and wastewater facilities.

Drinking Water Reservoirs and Pumping Systems

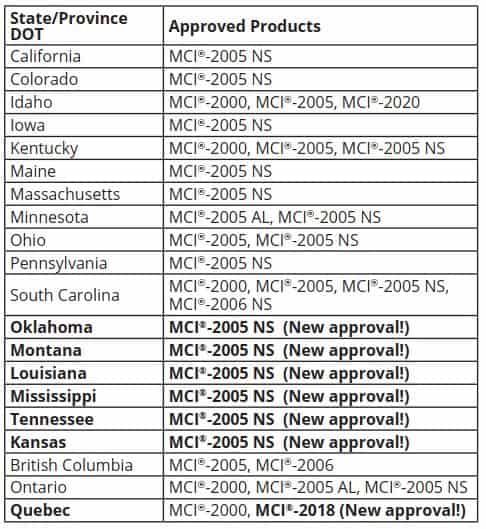

The first of these environments is the least corrosive. However, concrete drinking water reservoirs, piping, or pumping stations can still experience challenges from high exposure to moisture or due to long-term carbonation. One water consortium in Europe knew from experience that their structures were prone to corrosion and took care to minimize future damage by incorporating MCI®-2005 admixture into a new reservoir and water regulating tank. This concrete admixture is certified to meet ANSI/NSF Standard 61 for use in large potable water structures and so was a great corrosion inhibiting alternative to calcium nitrites, which are not certified in this way. Another product certified to meet NSF Standard 61 is MCI®-2020, which can be used for maintenance and corrosion mitigation on existing drinking water structures where carbonation may have set in.

Desalination Plants

Desalination plants are much more corrosive due to inevitable exposure to saltwater and brine. This is a built-in recipe for corrosion disaster. It is therefore imperative for desalination engineers to specify corrosion protection into the system in order to fight this ever-present challenge. The Sorek Desalination Plant is a great example of how and where MCI® can be used to fight desalination plant corrosion. MCI®-2005 was added along with a waterproofing admixture to both filtration bins and prefab concrete pipe segments. MCI®-2005 was also admixed into brine water reservoirs, where water likely reaches its peak chloride concentration. Furthermore, MCI®-2020 surface applied corrosion inhibitor (SACI) was used to compensate for low concrete cover in some desalinated water reservoirs. At least seven years later, no corrosion related issues had been reported.

Wastewater Treatment Plants and Pumping Stations

Last, but not least, wastewater treatment plants are among the most corrosive of these environments due to the high concentration of H2S and other contaminants present in the waste materials. Clarifiers, aeration tanks, secondary treatment bins, walkways, and pumping stations are often made of reinforced concrete and exposed to corrosive chemicals. The best plan is to specify MCI®-2005 or MCI®-2005 NS as a corrosion inhibiting admixture when the tanks or facilities are first poured. MCI®-2026 can be topically applied at any stage as a tough barrier in tanks or high traffic areas because of its outstanding resistance to chemicals and abrasion.

Promote Economic and Environmental Sustainability The presence of water, chlorides, and/or chemicals naturally adds to the risk of reinforced concrete corrosion. By taking advantage of a few key MCI® materials, facility designers and owners can raise the probability of extending service life for greater economic and environmental sustainability. Contact Cortec® for advice on your facility:

https://www.cortecmci.com/contact-us/

Keywords: sustainability, MCI, From Grey to Green, corrosion protection, concrete corrosion, concrete admixtures, carbon footprint, contributors to greenhouse gas emissions, wastewater treatment, extending service life