Category: Press Releases

PRESS RELEASE: How to Slow Down Corrosion with MCI® in High Temp GCC States

PRESS RELEASE: Contractors: Make Life Easier with MCI® Construction Site Coatings!

Construction is a challenging industry with tough working conditions, harsh weather, and unexpected delays. To make matters more difficult, workers are responsible for high value equipment and building materials that can easily be damaged on the job. Fortunately, contractors can make life easier for job crews by implementing three versatile Cortec® MCI® coatings for the construction site.

Protecting Rebar from Rust

Steel rebar can easily rust in transit or while stored onsite waiting to be used. Even worse, some projects are put on hold after work has started, leaving rebar half exposed and half embedded in concrete. An easy solution is to spray clean rebar with MCI® CorShield®, a water-based coating that cures to a soft non-tacky film and eventually hardens. Results of bond strength testing in accordance with ASTM A944-99 confirmed that MCI® CorShield® does not have to be removed prior to embedding in concrete, making it a highly convenient solution for interim protection during storage, transit, or construction delays.

Protecting Finished Surfaces

As a construction job progresses, new windows, frames, doors, and other finished surfaces are gradually added to the structure. Unfortunately, other work continues, so it is easy to damage these pristine surfaces by physical impact or paint/liquid spills. MCI® Peel-Off Coating offers a helpful way to protect non-porous walls, ceilings, floors, windows, and doorframes from untimely nicks, abrasion, scratches, corrosion, and overspray. This water-based coating sprays on like normal paint, but, when the job is done, workers can peel the coating off by hand and dispose it as solid waste.

Maintaining Concrete Equipment

Anyone who has worked on a concrete pour knows how difficult it can be to clean up concrete residue once it has hardened. This makes equipment maintenance especially difficult. Chipping concrete off a ready-mix truck is not a very practical option. A better choice is to apply MCI® Creteskin® to areas likely to be spattered with concrete mix. This industrial strength release agent contains corrosion inhibitors and is designed to prevent adhesion of cementitious materials, salts, and other abrasives to painted and unpainted metal surfaces so it is easier to rinse away the accumulated material at the end of the job. MCI® Creteskin® is a great idea for truck chassis, drum mixers, batching plants, concrete molds, scissor lifts, and other construction equipment.

Make Life Easier for Construction Workers

Construction is a demanding industry, but that does not mean it cannot be made easier and more efficient. The three MCI® specialty coatings above can be a great part of a strategy to do so. Contact Cortec® to learn more about these coatings for construction sites.

Keywords: MCI, construction site coatings, rebar rust, equipment maintenance, MCI coatings, rebar coating, window coating, concrete cleaning and removal, Cortec, construction delays

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

PRESS RELEASE: Another Tool for Your MCI® Concrete Maintenance/Repair Kit!

Water repellents play an important role in concrete maintenance and corrosion protection by blocking out certain corrosives and keeping in Migrating Corrosion Inhibitors. Because water repellents are sometimes applied alone or in conjunction with other concrete surface treatments, Cortec® has recently expanded its MCI® portfolio to include MCI®-2018 X, a 100% silane penetrating water repellent for concrete surfaces.

Water Repellent for Concrete

MCI®-2018 X is MCI®-2018 minus the Migrating Corrosion Inhibitors. Its primary function is to line concrete substrate pores with a hydrophobic layer that reduces the ingress of moisture, chlorides, and carbonation, thus extending the service life of the structure. If applied after a penetrating SACI (surface applied corrosion inhibitor), MCI®-2018 X prolongs the protection period of the corrosion inhibitor. MCI®-2018 X allows the surface to stay fully breathable and retain its original appearance.

Solving the SACI/Water Repellent Dilemma

In the past, MCI® customers sometimes faced the dilemma of whether to apply MCI®-2020 to get the highest concentration of MCI® SACIs on the market or whether to take advantage of the benefits of the two-in-one MCI®– 2018 water repellent with a lower concentration of Migrating Corrosion Inhibitors. While an even better option was to apply MCI®-2018 on top of MCI®-2020 for maximum protection, this could easily fall outside the project scope and budget. Now, if MCI® users want the high concentration of MCI®-2020 with only a water repellent on top, they can order MCI®-2018 X along with MCI®-2020 and be done with their search for a supplementary product.

When and Where to Use MCI®-2018 X

MCI®-2018 X can be used for routine maintenance every 5-10 years or used as part of the finishing touches to a concrete repair. Because it does not change the substrate’s appearance, MCI®-2018 X is a great option for historical restorations. As a silane water repellent, MCI®-2018 X has smaller molecules and adsorbs better into concrete than siloxane blends that can cause puddling, making MCI®-2018 X better for areas where slippage is a concern (e.g., steps, parking garage floors, and bridge decks). Other target applications include commercial buildings, tunnels, jetties/piers, and offshore oil platforms (non-submerged applications). MCI®-2018 X is also a good option for contractors who do not want to or need to pay extra for a corrosion inhibitor because their only purpose is to repel water on brick or stone surfaces that do not have underlying metal reinforcement.

How to Apply MCI®-2018 X

MCI®-2018 X can be applied by spray, roll, or brush to a clean concrete surface with a CSP 1-3 surface profile (per ICRI guidelines). As noted, MCI®-2020 may be applied first for additional corrosion protection. After a repair, fresh concrete should be allowed to cure 28 days before application of MCI®-2018 X. A dry surface is preferred for maximum penetration, although the second coat of MCI®-2018 X should be applied wet-on-wet over the first coat for best results.

A Customized Approach to Concrete Protection

The addition of MCI®-2018 X to the Cortec® portfolio helps contractors take a more customized approach to their selection of MCI® concrete surface treatments by adding a stand-alone water repellent to their concrete maintenance/repair kit. Used alone or in conjunction with MCI®-2020, MCI®-2018 X may be the logical choice to meet certain project protection and budget parameters. Contact Cortec® if you need more help deciding which concrete surface treatment combination is best for your next job.

Keywords: concrete maintenance, concrete repair, Migrating Corrosion Inhibitors, From Grey to Green, concrete water repellent, surface applied corrosion inhibitors, Cortec MCI, historical restoration, concrete protection, concrete breathability

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

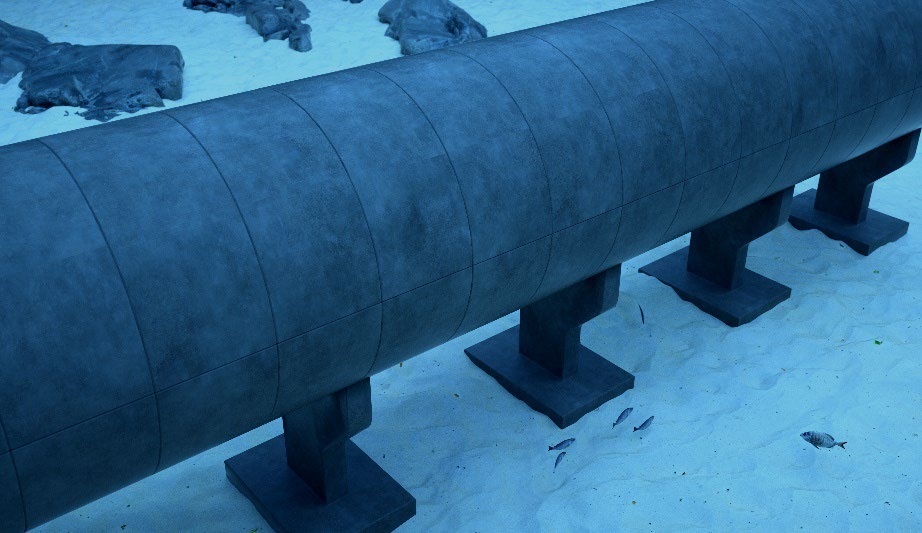

PRESS RELEASE: Preserving Capital Spares: A Strategy for Concrete-Coated Pipelines

Subsea oil and gas pipelines are frequently constructed by joining concrete-coated segments together. During construction, concrete-coated pipe may sit for six months to several years before installation. Capital spares are often ordered at the same time as the initial pipes but with a designed preservation life measured in decades of idle time. To ensure that these capital spares do not deteriorate prematurely, Cortec® shares several technologies and tips for preserving concrete-coated pipes from corrosion.

Challenges of Protecting Concrete-Coated Spares

Subsea pipe spares are often stored near the coast due to material handling difficulties. An incredibly long storage period and an aggressive environment combine to pose a frequently overlooked risk for long-term integrity. Although the concrete coating will initially protect the outside of each steel pipe segment, the concrete will absorb moisture, chlorides, and carbon dioxide over time, eventually leading to corrosion. Extreme temperature swings and sporadic inspection intervals can exacerbate the problem. To complicate matters, the concrete coating makes it difficult to access and treat the OD (outer diameter) of the steel pipe.

Migrating Corrosion Inhibitors to the Rescue

Migrating Corrosion Inhibitor™ (MCI®) Technology is typically used to protect reinforcing metals embedded in concrete because of its ability to travel through concrete pores to reach the surface of the underlying metal. The same mechanism makes MCI® suitable for protecting the metal pipe OD of concrete-coated pipe. Migrating Corrosion Inhibitors applied to the outside of the concrete pipe can gradually migrate as much as several inches into the concrete to form a protective anticorrosive molecular layer on the steel OD.

When to Preserve Capital Spares

Preservation of spare concrete-coated pipes should be done as soon as possible. Any delay gives moisture and chlorides a chance to start attacking the concrete and steel. Although preservation can be done later, additional rust removal and cleaning may be needed by then. In worst case scenarios, preservation may be neglected so long that corrosion compromises the integrity of pipe segments and new ones must be purchased, defeating the purpose of capital spares.

Protecting the Outer Diameter

If integrity is confirmed and surfaces are clean, the concrete surface may be treated with MCI®-2020. This topical solution has the highest concentration of Migrating Corrosion Inhibitors compared to other surface applied corrosion inhibitors (SACIs) on the market. For further protection, a water repellent can be added to hinder the entrance of additional moisture and chlorides while trapping the MCI® inside. Alternatively, MCI®-2018, which contains MCI® in a 100% silane water repellent, can be used alone or (for maximum protection) in conjunction with MCI®-2020. Both MCI®-2020 and MCI®-2018 are certified to meet ANSI/NSF Standard 61 for use in drinking water system components, making them attractive for those laying pipeline in environmentally protected waters where dangerous leachates are a concern for sea life.

Pipe Ends and Inner Diameter

Often, several inches on each end of a subsea pipe are not coated with concrete. Here, MCI® CorShield® can be applied to protect the exposed metal. This water-based removable coating provides excellent protection in unsheltered outdoor environments and cures to a soft non tacky film that eventually hardens. If the capital spares need to be installed, the coating can be removed with an alkaline cleaner, if desired.

The inner diameter (ID) of the pipeline segment should also be protected by fogging it with CorroLogic® Fogging Fluid VpCI®-339. This chemistry is similar to MCI® and migrates through void spaces to form a molecular protective layer that remains as long as the void stays closed. To meet this requirement and keep debris out, workers should cap the ends of each pipe segment with a material such as MilCorr® VpCI® Shrink Film, a heavy duty plastic that also contains corrosion inhibitors. Once this is done, the spares can be left alone and checked once or twice a year.

Keep Your Capital Spares On-Call

Even though the need to install concrete-coated pipe spares may be unpredictable, these capital spares should remain on-call for emergency or routine replacement. Proper preservation helps oil and gas companies do so, keeping pipeline segments ready to use on short notice. Contact Cortec® to learn more about preservation of oil and gas capital spares with MCI®.

Keywords: capital spares, preserving concrete coated pipeline, subsea pipelines, Cortec, Cortec MCI, Migrating Corrosion Inhibitors, pipeline corrosion, pipeline storage, oil and gas spares, concrete weight coating

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

PRESS RELEASE: Fight Corrosion in Concrete Potable Water Structures with MCI®!

What can be done when corrosion protection is needed in a reinforced concrete structure that holds drinking water or is located in an environmentally sensitive waterway? Due to the possibility of harmful chemicals leaching into water, contractors are limited on which products they can apply to concrete elements in contact with potable water. Fortunately, Cortec® Corporation offers a variety of Migrating Corrosion Inhibitor™ products that are certified to meet ANSI/NSF Standard 61 for use in drinking water system components.

How Migrating Corrosion Inhibitors Work

Migrating Corrosion Inhibitors (MCIs) can be admixed into new concrete and repair mortar or topically applied to existing concrete as a surface applied corrosion inhibitor (SACI). MCI® molecules migrate through concrete pores and are attracted to metal surfaces, such as rebar, where they form a molecular protective layer considered to be ambiodic, or mixed, meaning it inhibits corrosion reactions at both the anode and cathode of a potential corrosion cell.

MCI® Admixtures for Drinking Water Components

MCI® admixtures are sometimes desired for extra protection in potable water reservoirs, prefab pipe segments for transporting seawater to desalination plants, brine holding tanks, and seawalls in sensitive areas where there are leachate concerns. MCI® admixtures certified to meet NSF Standard 61 for use in drinking water system components include the following:

- MCI®-2005 – A liquid corrosion inhibiting admixture. MCI®-2005 is a USDA Certified Biobased Product that can be mixed into new concrete on the jobsite or at the batching plant. MCI®-2005 retards set time, making it a welcome alternative to calcium nitrite on

extremely warm days. - MCI®-2005 NS – A normal set version of MCI®-2005 that does not accelerate or retard set time.

- MCI®-2006 NS – A powder MCI® admixture that does not accelerate or retard set time. It is often used in repairs.

MCI® SACIs for Drinking Water Components

MCI® SACIs are typically sprayed onto existing concrete and migrate deeper over time. They can be a great option when application errors in the construction of potable water holding tanks have left a thinner concrete cover than intended and additional corrosion protection is needed. They can also be used for periodic maintenance on structures (e.g., concrete water towers) that were not initially specified with MCI® admixtures but where there is a corrosion concern. The following SACIs are among those certified to meet NSF Standard 61 for use in drinking water system components:

- MCI®-2020 – A water-based, highly concentrated dose of Migrating Corrosion Inhibitors.

- MCI®-2018 – Migrating Corrosion Inhibitors combined with a 100% silane based water repellent (a waterproofing membrane should be used when the component will be under hydrostatic pressure).

Extend Service Life of Concrete Potable Water Structures

Corrosion in reinforced concrete structures leads to costly repairs, interrupting the intended use of the structure and potentially reducing its service life. Specifying an MCI® admixture in new drinking water system components at risk for corrosion or periodically applying a maintenance dose of MCI® SACIs to existing tanks and structures can be an excellent way to slow down the natural deterioration processes of corrosion in drinking water system components where higher safety standards exist. Contact Cortec® to learn more about using MCI® to protect potable water structures.

Keywords: alternatives to calcium nitrite, NSF Standard 61, corrosion inhibitors for drinking water components, corrosion inhibitors for potable water, concrete maintenance, from grey to green, Cortec MCI, rusted rebar in concrete, water tower maintenance, concrete admixtures

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

PRESS RELEASE: Get Rid of Oily Residues With Biological Cleaner Oil-Eating Microbes Keep Floors a Safe Environment!

Petroleum-based stains on floors are very difficult to clean, sometimes requiring blasting to remove. Cortec® Corporation developed simple and efficient solution relying on green chemistry to chase after the oily residues on the substrate floor.

With environmentally friendly cleaner- MCI®-2061, removing oil stains off the repair shop floor or driveway is no longer complicated. This biological cleaner/degreaser is excellent for getting rid of oily residues on the garage floors, gas stations or parking lots without requiring harsh chemicals or solvents. MCI®-2061 is formulated for cleaning concrete, asphalt and other hard surfaces such as fixtures and equipment. Its unique formulation combines powerful cleaning chemistry with microorganisms capable of biodegrading hydrocarbons that stain concrete and other hard surfaces. Biodegradable surfactants loosen and disperse hydrocarbons, making them more available to microbes that eat them. The main benefits are:

1. Microbes of MCI®-2061 populate the substrate and provide residual deep cleaning action as they chase the oil stain through the pores.

2. MCI®-2061 biochemistry is safe on floors and does not corrode or harm them.

MCI®-2061 will degrade a wide range of hydrocarbons including gasoline, diesel, crude oil, benzene, toluene, ethyl benzene and xylene.

How the technology works?

MCI®-2061 is used like other hard-surface cleaners. The initial cleaning action is due to the surfactant component of the product, and secondary cleaning action is due to the microorganism component. The microorganisms are preserved bacterial spores that remain inactive until MCI®– 2061 is applied. The spores then germinate into active microorganisms. Microorganisms that remain behind after the water rinse continue digesting hydrocarbon residuals on the driveway or

shop floor. Furthermore, microorganisms that are rinsed downstream into drain lines, sewer systems, or grease traps can help accelerate the biodegradation of the waste.

WHERE TO USE:

- Parking Garages, Bridges, Roads

- Gas Stations and Oil Change Stations

- Petroleum Processing Plants

- Warehouses

- Biological Parts Washers

- Many other surfaces contaminated with hydrocarbon materials

MCI®-2061 is non-toxic, it deep cleans surfaces and reduces pollution. Health and safety hazards are also significantly reduced compared to standard solvent or alkali based cleaners. With biodegradable surfactants, a neutral pH, no solvents or VOC’s, MCI®-2061 makes it easy to maintain a cleaner and healthier facility utilizing green technology.

Keywords: biological cleaner, sustainability, green inhibitors, corrosion protection, concrete, MCI, asphalt, floor cleaner, corrosion inhibitors

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

PRESS RELEASE: Fighting the Danger of Overprotection on Concrete Repairs (MCI® SACIs)

Is it possible to give concrete too much protection against reinforcement corrosion? Research indicates that this is so, although no consensus exists on the exact mechanisms and how to avoid it. However, following logical reasoning, Cortec® recommends applying Migrating Corrosion Inhibitors (MCI® SACIs) to mitigate the problem.

What Is Overprotection?

Overprotection occurs when metal reinforcement in one part of the concrete is more protected than in another. This can happen when a new concrete patch is laid, replacing contaminated or carbonated concrete with uncontaminated concrete that has a high pH and therefore a naturally protective alkaline environment. The resulting difference in corrosion potential between the patch and the adjacent concrete eventually leads to corrosion in surrounding areas, thus transferring the original problem elsewhere. This is known as the ring anode / halo effect.

Examples of Overprotection

Overprotection can also happen in a variety of other ways. One is through the common practice of cathodic protection (CP). The challenge of calculating the appropriate number of anodes for an area and removing concrete to install them is compounded by the fact that it is not possible to gain access to and treat all parts of the rebar equally. This leaves some portions of the metal reinforcement with more protection than others, an imbalance that could show itself over time by corrosion in areas with less protection. A similar effect may happen with the application of an epoxy coating to one part of a rebar and not to another. Using other corrosion protection measures may cause a similar imbalance when overapplied.

Even Out the Corrosion Potential

The use of MCI® Surface Applied Corrosion Inhibitors (SACIs) makes it easier to balance out the corrosion potential. Rather than leaving a well-protected patch surrounded by chloride-contaminated concrete, contractors can apply MCI® SACIs to the undisturbed concrete in an effort to reduce the difference in corrosion potential between two portions. Fortunately, MCI® SACIs are easy to apply by spraying onto the concrete like a standard surface treatment. As time progresses, Migrating Corrosion Inhibitors in the MCI® SACI work their way deeper in through the concrete pores toward the metal reinforcement. Their affinity to metal allows them to form a protective molecular layer on the embedded rebar when they encounter it.

MCI® SACI Options

MCI®-2020 contains the highest concentration of surface applied Migrating Corrosion Inhibitors on the market and is therefore the number one recommended SACI for this purpose. Typically, a coating or water repellent should be applied on top of this to keep moisture out and MCI® in. Two-in-one MCI®/ water repellents are also available for greater convenience, albeit with smaller doses of Migrating Corrosion Inhibitors (MCI®-2018 combines MCI® with a 100% silane water repellent, and MCI®-2019 combines MCI® with a 40% silane water repellent).

Take a Balanced Approach to Corrosion Protection

Concrete repairs are too labor-intensive to make the mistake of overprotection. By being sure to protect the concrete around the patch area with Migrating Corrosion Inhibitors, contractors can take one step ahead of the chain reaction of corrosion that is common in less protected areas. Contact Cortec® to learn more about the advantages of mitigating corrosion in reinforced concrete with MCI®.

Keywords: halo effect, ring anode effect, concrete repairs, overprotection on concrete, Cortec, MCI, Migrating Corrosion Inhibitors, rusted rebar in concrete, concrete corrosion, corrosion inhibitors in concrete

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

PRESS RELEASE: Winter’s Coming: What’s Your PT Corrosion Inhibitor Plan for Grouting Delays?

October 30, 2023

Winter weather and freezing temperatures will soon mean that construction projects are delayed in many parts of the Northern Hemisphere. For concrete PT (post-tensioning) structures such as bridges or parking ramps, this delays the grouting that should be done as quickly as possible after the placement of bonded PT strands. Cortec® MCI®-309 is an outstanding solution to counteract corrosion during this critical period of grouting delays.

Corrosion and Grouting Delays

Grouting delays may range from a few days to several months depending on site conditions and circumstances, the severity of the temperatures, and weather. During delays, metal tendons that have been placed inside the PT duct but not enveloped in grout are exposed to oxygen, the potential ingress of moisture, and (depending on proximity to the sea) even chlorides. In the US, state and federal requirements typically call for corrosion inhibitor application if the waiting period is seven to 20 days or longer (each DOT has different requirements). While oil-based corrosion inhibitors offer some protection, they can have a negative impact on bond strength once tendons are grouted.

The Migrating Corrosion Inhibitor™ Advantage

The best option on the market for corrosion protection of PT tendons that have been installed but not grouted is MCI®-309. This Migrating Corrosion Inhibitor™ powder is easily fogged through ducts using a low-pressure air hose and sandblast cup—no special equipment required. MCI®-309 releases corrosion inhibiting vapors that diffuse throughout the entire void space. An attraction to metal allows the corrosion inhibitors to adsorb onto tendons, forming a protective molecular layer. When better weather comes, grout can be applied as normal without flushing the corrosion inhibitor out of the duct.\

MCI®-309 ‘Claims to Fame’

MCI®-309 has been used in a wide variety of construction projects, ranging from the Samuel De Champlain Bridge in Quebec to the extradosed St. Croix River Crossing bridge near Cortec® World Headquarters in Minnesota. It has been used in Washington, DC, for the Frederick Douglass Memorial Bridge Project and in the Middle East and Hawaii for non-winter-related grouting delays. Due to its migrating ability, MCI®-309 can also be and has been used for corrosion protection in other void space applications, such as flex-float structures at the Round Butte Reservoir where painting hard-to-reach internals of the ballast areas was impractical and MCI®-309 provided a much better alternative.

Get Ready for Winter Construction Delays

By planning now for possible construction delays this winter, contractors can be prepared with a stock of MCI®-309 to protect PT strands that must be placed but cannot be immediately grouted. To learn more about MCI®-309 specifics and how they apply to your PT project, contact Cortec® today.

Keywords: winter construction, grouting delays, corrosion inhibitors, bridge construction, post-tensioning structures, Cortec, MCI, prevent corrosion in PT ducts, bridge contractors, corrosion inhibitor bond strength

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

PRESS RELEASE: Five Questions to Optimize MCI® / Water Repellent Selection!

Planning makes a significant difference in practically any area of life—not less so in concrete construction and repair. Engineers and project owners setting out on a new job can benefit by asking the right questions about their project goals, conditions, and current specifications. When it comes to selecting water repellents and corrosion inhibitors for construction and repair projects, Cortec® MCI® suggests asking the following questions to guide the decision-making process and optimize results.

Is the Project New Construction or Concrete Repair?

The first obvious question to consider is whether the project involves a new or existing structure. Corrosion inhibiting admixtures followed by a waterproofing membrane on the concrete surface are more common for new structures; while water repellents, waterproofing membranes, and MCI® surface applied corrosion inhibitors (SACIs) are more commonly applied to existing structures.

What Is the Current State of the Structure?

For concrete structures in need of repair, examining current conditions will help engineers understand why the repair is needed and help guide their repair philosophy. For instance, if the concrete has cracking and leakage, the engineer will need to determine how to correct the underlying problem. Engineers may also evaluate the depth of carbonation, the concentration of chlorides present, and the degree of metal loss on the rebar. The presence of carbonation or chlorides could signal the need to cut out as much of the old concrete as possible and use an SACI such as MCI®-2020 before applying a waterproofing membrane. Otherwise, the “disease” will be trapped underneath the membrane, allowing the corrosion process to continue, and deteriorating the structure from the inside out. If reinforcement bars have been substantially eaten away by corrosion, engineers may recommend replacing them. If enough metal remains, they may either mechanically clean and remove the corrosion products or chemically treat them with CorrVerter® MCI® to passivate the rebars.

What Kind of Water Exposure Is Expected?

A concrete floor in the middle of a residential building is likely to have little or no exposure to damaging water or corrosives and therefore may require no corrosion inhibitors, water repellents, or waterproofing. In contrast, concrete structures that will be in direct contact with water, as in the case of a concrete substructure exposed to a high water table, may require an MCI® admixture or SACI in addition to a waterproofing membrane. Other structures may only need a dual water repellent / SACI such as MCI®– 2018 or MCI®-2019 to provide adequate protection where there is exposure to moisture but not constant hydrostatic pressure.

What Is the Desired Service Life and Maintenance Schedule?

Another important factor to consider is the desired service life and maintenance intervals. MCI® admixtures such as MCI®– 2005 can greatly extend service life predictions in new structures at a lower cost compared to other strategies such as the use of epoxy coated rebar. The use of corrosion inhibitors in conjunction with water protection systems can further enhance the service life. When it comes to existing structures, project owners who want repairs to last 20 years without maintenance can use an SACI such as MCI®-2020 followed by a waterproofing membrane, since membrane systems typically carry 20+ year warranties. However, some DOTs reapply water repellents every five years as part of their routine maintenance and will be very satisfied with the 7-10 year reapplication recommendation for MCI®-2018 or MCI®-2019 two-in-one SACI water repellents.

What Is the Current Specification?

One other question that could seem irrelevant but can actually be very helpful to ask is what products have been previously used or are currently specified. For instance, if a water repellent has already been applied, a water-based SACI such as MCI®-2020 will not be able to penetrate the concrete pores and should be replaced by MCI®-2019, which can be applied on top of other partially remaining silane water repellents. Talking with engineers about what products are typically used can also make it easier to identify areas of potential waste—sometimes MCI®-2018 is really all that is needed instead of both MCI®-2020 and a waterproofing membrane!

Make the Most of Your Concrete Project

There are many considerations that go into the choice of water repellents and corrosion inhibitors for new structures and concrete repairs. Asking the questions above can be a simple way to make the most of a concrete repair or new construction project by selecting the most helpful products and eliminating unnecessary or inappropriate ones. Contact Cortec® MCI® for further help choosing a tailored combination of MCI® and water repelling materials.

Keywords: concrete corrosion, rusted rebar in concrete, corrosion inhibitors in concrete, Cortec, MCI, From Grey to Green, concrete repair, water repellent, SACI, surface applied corrosion inhibitor

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.